English

| Availability: | |

|---|---|

| Quantity: | |

YHZS35/YHZS50/YHZS75/YHZS100

CHEN LI

PRODUCT SPECIFICATIONS

| Product Name | Mobile Concrete Batching Plant | |||

| Model | YHZS35 | YHZS50 | YHZS75 | YHZS100 |

| Theoretical Productivity(m3/h) | 35 | 50 | 75 | 100 |

| Mixer | JS1250/750 | JS1500/1000 | JS2250/1500 | JS3000/2000 |

| Batching System | PLD1200 | PLD1600 | PLD2400 | PLDProduct Specifications3200 |

| Discharge Height | 3.8m | 3.8m | 3.8m | 3.8m |

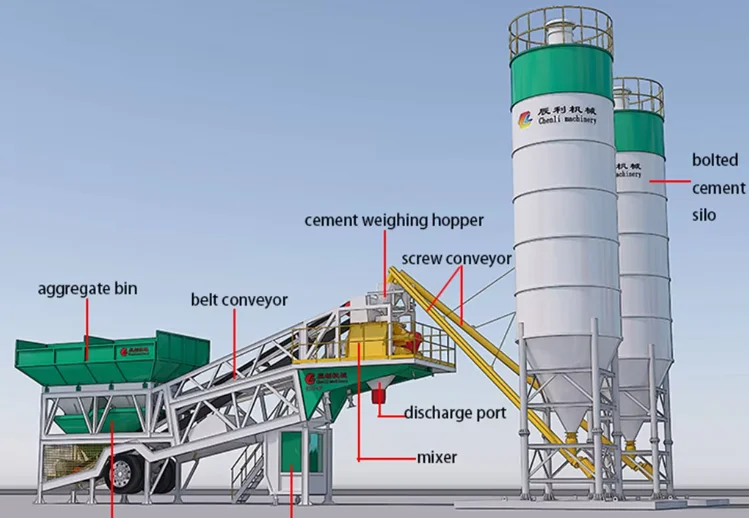

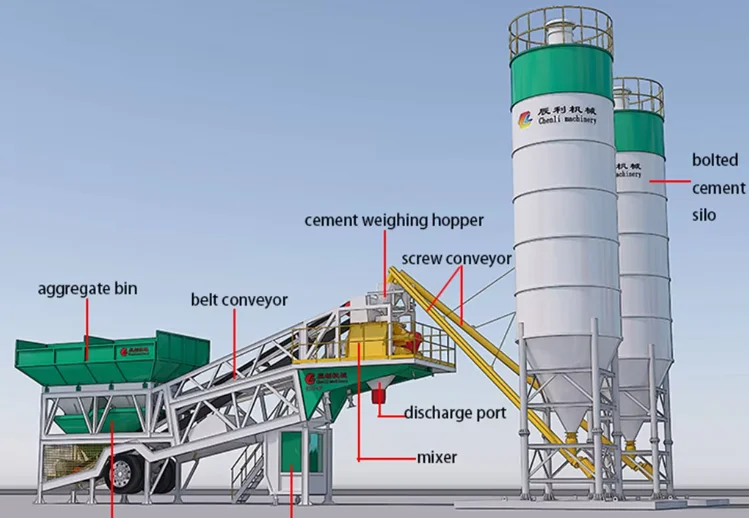

Main components(The following is for reference only and can be customized):

1. Mixing system

①Mixing drum system ②Drivetrain ③Sealing and lubrication systems ④Unloading system

2. Batching system

①Machine frame ②Storage silo ③Weighing bucket ④Belt conveyor

3. Powder metering system

4. Liquid metering device

5. Hopper

6. Water, admixture pipelines, and gas systems

7. Exterior spraying

8. Control system

PRODUCT REAL SHOT PICTURES

FEATURES AND ADVANTAGES OF PRODUCTS AND TECHNOLOGIES

PRODUCT FEATURES AND ADVANTAGES

*High Metering Precision:

The aggregate, cement, water, and admixture mixing stations each have their own electronic weighing system. Advanced control modes and mechanical structures enable precise metering and vibration metering technology for accurate measurement.

*High Automation:

The electrical control system utilizes a microcomputer-based control system, enabling automated metering, conveying, lifting, mixing, and unloading functions. Operation is both automatic and manual, ensuring ease of use. (A simplified centralized control option is available, depending on user requirements.)

*Excellent Mixing Performance:

Our company manufactures advanced YJS or JS series forced twin-shaft mixers. Liners and blades are made of wear-resistant cast iron, with optimized angles for excellent mixing performance, high speed, and a long service life. (YJN series vertical-shaft planetary mixers are also available upon request.)

*High Reliability:

The system hardware features a standardized and modular structure, offering flexible configuration and strong scalability, as well as exceptional stability and reliability. Hardware and electronic control components from internationally renowned brands such as Siemens and Omron are available directly from the market, completely eliminating user concerns. One machine, dual controls: Equipped with an industrial touchscreen, even if the main unit fails and cannot control normal production, the touchscreen can be used to control production, ensuring normal operation.

*Easy and convenient relocation:

The main equipment of the mixing station adopts a trailer chassis design, integrating the batching machine, conveyor, mixer, control room, various weighing systems, and additive system (powder silo and screw conveyor can also be integrated). The rational spatial layout makes it easy to move and use, and can be quickly installed on site.

TECHNICAL (SYSTEM) CHARACTERISTICS AND ADCANTAGES

Technical Features:

A. Advanced Control Mode

1. The control system utilizes a programmable controller and weighing instrument at the lower level, and a host computer and industrial touch screen (optional) at the upper level. Using RS232/PPI protocol communication, the system accurately displays the operating status of all motors, assembly parameters, scale weights, and control and operation information on the screen in real time. Operations are controlled through the host computer. The host computer, acting as the host computer, manages system data, historical records, and operating parameter adjustments. During normal operation, the host computer operates independently; in the event of a failure, the industrial touch screen takes over.

2. The control interface utilizes a fully WYSIWYG graphical display for rapid user experience and reliable control. All required operating records and recipe data can be stored in unlimited quantities on the computer or printed out.

3. For high-performance concrete production processes, multiple mixing cycles are supported to achieve the desired performance.

B. High-Quality Hardware Configuration

1. Features include high reliability, superior performance, flexible configuration, easy installation, and convenient maintenance. The program utilizes EPROM storage technology, ensuring a zero-failure system. 2. The control system boasts an internationally advanced level, utilizing electrical components, programmable controllers, and computers from renowned international brands.

3. The system hardware features a standardized and modular structure, offering flexible configuration and strong scalability. The system also boasts high stability, reliability, and maintainability.

4. All system hardware and electronic control components can be purchased directly from the market, completely eliminating user concerns.

C. Safe and Effective Anti-Interference Measures

1. To reduce interference from noise, low-frequency drift, and other sources, improve the signal-to-noise ratio, and suppress common-mode and pulse interference, the system utilizes a complex software filtering method within the software.

2. All signals entering and exiting the system are isolated using intermediate relays, ensuring signal accuracy and anti-interference capabilities.

3. Power supply purification, voltage stabilization, and isolation technology.

D. Excellent Control Performance

1. Tightly controlled interlocking and interlocking protections for the mixing unit, flat belt, and inclined belt minimize operational errors. Audible and visual alarms indicate when key equipment is not operating, resulting in a high degree of automation and significantly improved operational efficiency. 2. Automated control and real-time dynamic simulation display are achieved for the entire batching, mixing, and discharging process.

3. The weighing instrument directly controls batching. Sensor signals from each scale are fed directly to the weighing instrument without conversion, resulting in faster weight signal acquisition. Dynamic correction of weighing drop (via real-time material flow detection) and intelligent pulse automatic re-weighing and deduction are also included. The system's dynamic control accuracy is unmatched by previous control systems.

4. All production operation parameters, alarm parameters, and debugging parameters are fully accessible to the user, providing flexible control and simple operation.

5. Key production parameters can be adjusted directly on the production control screen.

6. Manual intervention is possible during the automated control process.

7. The metering system features automatic zero tracking and automatic zero adjustment.

8. The control system's safe operation mode effectively prevents operator fatigue and errors.

E. Comprehensive auxiliary and management functions

1. Production data is automatically recorded and backed up in a categorized manner. 2. A one-click computer restore function allows the computer to be restored to its factory default state in just minutes if the computer software malfunctions for any reason, ensuring trouble-free system operation.

3. Equipped with a high-definition camera monitor, the entire mixing plant can be monitored from the operator's room.

4. All production data can be printed, with flexible and customizable printing options.

F. Unparalleled Error Correction, Permission Settings, and Operation Logs

1. The system features maximum value memory and automatic reset for critical control parameters, mix ratios, and volume.

2. The system administrator can assign login passwords to each operator and set operating permissions for each window, effectively preventing unauthorized operation.

3. The PLC handles the acquisition, analysis, processing, display, and control of system signals and production data. This ensures excellent system stability, reliability, and maintainability.

Technical Advantages:

A. The advanced control system is powerful, stable, reliable, and provides precise metering. The aggregate system also features an overload protection function that automatically stops aggregate discharge and issues an audible and visual alarm when overloading occurs. B. Fully computerized operation makes the system easy to learn, convenient, and fast to operate. System failure recovery is fast, with a one-click restore function.

C. Dynamic production screens are organized by function, providing a clear and intuitive overall effect, making system operation and observation easier. Key controllable system parameters can be modified directly on the main control simulation screen, making parameter adjustments quick and easy. The system features multi-level permissions based on management levels, effectively preventing unauthorized operation.

D. Real-time modification of water formulas allows for more convenient and efficient slump control.

E. Basic system parameters and production control parameters are displayed in an open operation window, giving users complete control over the equipment's operating performance.

F. The system's key control parameters feature intelligent memory and automatic error correction, completely preventing major errors caused by accidental operation.

G. The system utilizes a fully Chinese platform, offering simple and intuitive screens, accurate and stable measurement, simple and convenient operation, remote service support, and automatic fault diagnosis for timely and accurate problem resolution. The control system utilizes bus control, offering strong scalability, security, and reliability. 3) Safety Protection System Overview

To prevent operator safety hazards and further escalation of electrical equipment accidents caused by insulation damage in electrical equipment or devices, the following safety protection design measures are implemented for electrical control equipment:

A. Insulation Performance of Electrical Control Equipment

1. The test voltage for the high-voltage control circuit must meet the following requirements: 1.5 kV/50 Hz/1 minute without breakdown.

2. The insulation resistance of the high-voltage control circuit must be greater than 0.5 megohms when measured with a 1 kV megohmmeter, or greater than 1 megohm when measured with a 0.5 kV megohmmeter.

3. The control panel buttons must be DC 24V, eliminating the risk of electric shock.

B. Cable Requirements

Use national standard rubber-plastic sheathed cables, and use cable protection brackets or troughs for wiring.

C. Power Sockets

Wiring must comply with the "left neutral, right live" requirement.

D. Protective Grounding and Grounding Devices for Electrical Control Equipment

The equipment must have reliable lightning protection and electrical protection facilities, as well as a safe and reliable grounding device. F. Emergency Procedures

Emergency stop buttons are located near the operating console, mixer, and conveyor belt to shut off power to the entire control system in an emergency.

G. Motor Protection

Overcurrent, undervoltage, overvoltage, phase loss, and power failure protection are all provided.

PRODUCT SPECIFICATIONS

| Product Name | Mobile Concrete Batching Plant | |||

| Model | YHZS35 | YHZS50 | YHZS75 | YHZS100 |

| Theoretical Productivity(m3/h) | 35 | 50 | 75 | 100 |

| Mixer | JS1250/750 | JS1500/1000 | JS2250/1500 | JS3000/2000 |

| Batching System | PLD1200 | PLD1600 | PLD2400 | PLDProduct Specifications3200 |

| Discharge Height | 3.8m | 3.8m | 3.8m | 3.8m |

Main components(The following is for reference only and can be customized):

1. Mixing system

①Mixing drum system ②Drivetrain ③Sealing and lubrication systems ④Unloading system

2. Batching system

①Machine frame ②Storage silo ③Weighing bucket ④Belt conveyor

3. Powder metering system

4. Liquid metering device

5. Hopper

6. Water, admixture pipelines, and gas systems

7. Exterior spraying

8. Control system

PRODUCT REAL SHOT PICTURES

FEATURES AND ADVANTAGES OF PRODUCTS AND TECHNOLOGIES

PRODUCT FEATURES AND ADVANTAGES

*High Metering Precision:

The aggregate, cement, water, and admixture mixing stations each have their own electronic weighing system. Advanced control modes and mechanical structures enable precise metering and vibration metering technology for accurate measurement.

*High Automation:

The electrical control system utilizes a microcomputer-based control system, enabling automated metering, conveying, lifting, mixing, and unloading functions. Operation is both automatic and manual, ensuring ease of use. (A simplified centralized control option is available, depending on user requirements.)

*Excellent Mixing Performance:

Our company manufactures advanced YJS or JS series forced twin-shaft mixers. Liners and blades are made of wear-resistant cast iron, with optimized angles for excellent mixing performance, high speed, and a long service life. (YJN series vertical-shaft planetary mixers are also available upon request.)

*High Reliability:

The system hardware features a standardized and modular structure, offering flexible configuration and strong scalability, as well as exceptional stability and reliability. Hardware and electronic control components from internationally renowned brands such as Siemens and Omron are available directly from the market, completely eliminating user concerns. One machine, dual controls: Equipped with an industrial touchscreen, even if the main unit fails and cannot control normal production, the touchscreen can be used to control production, ensuring normal operation.

*Easy and convenient relocation:

The main equipment of the mixing station adopts a trailer chassis design, integrating the batching machine, conveyor, mixer, control room, various weighing systems, and additive system (powder silo and screw conveyor can also be integrated). The rational spatial layout makes it easy to move and use, and can be quickly installed on site.

TECHNICAL (SYSTEM) CHARACTERISTICS AND ADCANTAGES

Technical Features:

A. Advanced Control Mode

1. The control system utilizes a programmable controller and weighing instrument at the lower level, and a host computer and industrial touch screen (optional) at the upper level. Using RS232/PPI protocol communication, the system accurately displays the operating status of all motors, assembly parameters, scale weights, and control and operation information on the screen in real time. Operations are controlled through the host computer. The host computer, acting as the host computer, manages system data, historical records, and operating parameter adjustments. During normal operation, the host computer operates independently; in the event of a failure, the industrial touch screen takes over.

2. The control interface utilizes a fully WYSIWYG graphical display for rapid user experience and reliable control. All required operating records and recipe data can be stored in unlimited quantities on the computer or printed out.

3. For high-performance concrete production processes, multiple mixing cycles are supported to achieve the desired performance.

B. High-Quality Hardware Configuration

1. Features include high reliability, superior performance, flexible configuration, easy installation, and convenient maintenance. The program utilizes EPROM storage technology, ensuring a zero-failure system. 2. The control system boasts an internationally advanced level, utilizing electrical components, programmable controllers, and computers from renowned international brands.

3. The system hardware features a standardized and modular structure, offering flexible configuration and strong scalability. The system also boasts high stability, reliability, and maintainability.

4. All system hardware and electronic control components can be purchased directly from the market, completely eliminating user concerns.

C. Safe and Effective Anti-Interference Measures

1. To reduce interference from noise, low-frequency drift, and other sources, improve the signal-to-noise ratio, and suppress common-mode and pulse interference, the system utilizes a complex software filtering method within the software.

2. All signals entering and exiting the system are isolated using intermediate relays, ensuring signal accuracy and anti-interference capabilities.

3. Power supply purification, voltage stabilization, and isolation technology.

D. Excellent Control Performance

1. Tightly controlled interlocking and interlocking protections for the mixing unit, flat belt, and inclined belt minimize operational errors. Audible and visual alarms indicate when key equipment is not operating, resulting in a high degree of automation and significantly improved operational efficiency. 2. Automated control and real-time dynamic simulation display are achieved for the entire batching, mixing, and discharging process.

3. The weighing instrument directly controls batching. Sensor signals from each scale are fed directly to the weighing instrument without conversion, resulting in faster weight signal acquisition. Dynamic correction of weighing drop (via real-time material flow detection) and intelligent pulse automatic re-weighing and deduction are also included. The system's dynamic control accuracy is unmatched by previous control systems.

4. All production operation parameters, alarm parameters, and debugging parameters are fully accessible to the user, providing flexible control and simple operation.

5. Key production parameters can be adjusted directly on the production control screen.

6. Manual intervention is possible during the automated control process.

7. The metering system features automatic zero tracking and automatic zero adjustment.

8. The control system's safe operation mode effectively prevents operator fatigue and errors.

E. Comprehensive auxiliary and management functions

1. Production data is automatically recorded and backed up in a categorized manner. 2. A one-click computer restore function allows the computer to be restored to its factory default state in just minutes if the computer software malfunctions for any reason, ensuring trouble-free system operation.

3. Equipped with a high-definition camera monitor, the entire mixing plant can be monitored from the operator's room.

4. All production data can be printed, with flexible and customizable printing options.

F. Unparalleled Error Correction, Permission Settings, and Operation Logs

1. The system features maximum value memory and automatic reset for critical control parameters, mix ratios, and volume.

2. The system administrator can assign login passwords to each operator and set operating permissions for each window, effectively preventing unauthorized operation.

3. The PLC handles the acquisition, analysis, processing, display, and control of system signals and production data. This ensures excellent system stability, reliability, and maintainability.

Technical Advantages:

A. The advanced control system is powerful, stable, reliable, and provides precise metering. The aggregate system also features an overload protection function that automatically stops aggregate discharge and issues an audible and visual alarm when overloading occurs. B. Fully computerized operation makes the system easy to learn, convenient, and fast to operate. System failure recovery is fast, with a one-click restore function.

C. Dynamic production screens are organized by function, providing a clear and intuitive overall effect, making system operation and observation easier. Key controllable system parameters can be modified directly on the main control simulation screen, making parameter adjustments quick and easy. The system features multi-level permissions based on management levels, effectively preventing unauthorized operation.

D. Real-time modification of water formulas allows for more convenient and efficient slump control.

E. Basic system parameters and production control parameters are displayed in an open operation window, giving users complete control over the equipment's operating performance.

F. The system's key control parameters feature intelligent memory and automatic error correction, completely preventing major errors caused by accidental operation.

G. The system utilizes a fully Chinese platform, offering simple and intuitive screens, accurate and stable measurement, simple and convenient operation, remote service support, and automatic fault diagnosis for timely and accurate problem resolution. The control system utilizes bus control, offering strong scalability, security, and reliability. 3) Safety Protection System Overview

To prevent operator safety hazards and further escalation of electrical equipment accidents caused by insulation damage in electrical equipment or devices, the following safety protection design measures are implemented for electrical control equipment:

A. Insulation Performance of Electrical Control Equipment

1. The test voltage for the high-voltage control circuit must meet the following requirements: 1.5 kV/50 Hz/1 minute without breakdown.

2. The insulation resistance of the high-voltage control circuit must be greater than 0.5 megohms when measured with a 1 kV megohmmeter, or greater than 1 megohm when measured with a 0.5 kV megohmmeter.

3. The control panel buttons must be DC 24V, eliminating the risk of electric shock.

B. Cable Requirements

Use national standard rubber-plastic sheathed cables, and use cable protection brackets or troughs for wiring.

C. Power Sockets

Wiring must comply with the "left neutral, right live" requirement.

D. Protective Grounding and Grounding Devices for Electrical Control Equipment

The equipment must have reliable lightning protection and electrical protection facilities, as well as a safe and reliable grounding device. F. Emergency Procedures

Emergency stop buttons are located near the operating console, mixer, and conveyor belt to shut off power to the entire control system in an emergency.

G. Motor Protection

Overcurrent, undervoltage, overvoltage, phase loss, and power failure protection are all provided.