English

| Availability: | |

|---|---|

| Quantity: | |

SLHB-8/10/15/20/30、LQY-10/15/30/40/60/80

ChenLi

PRODUCT SPECIFICATIONS

| Model | SLHB-8 | SLHB-10 | SLH8-15 | SLHB-20 | SLHB-30 | |

| Capacity | 8t/h | 10t/h | 15t/h | 20 t/h | 30 t/h | |

| Total Power | Diesel | 23kw | 27 kw | 32 kw |

45 kw | 63 kw |

| Coal | 39 kw | 43 kw | 51 kw | 70 kw | 84 kw | |

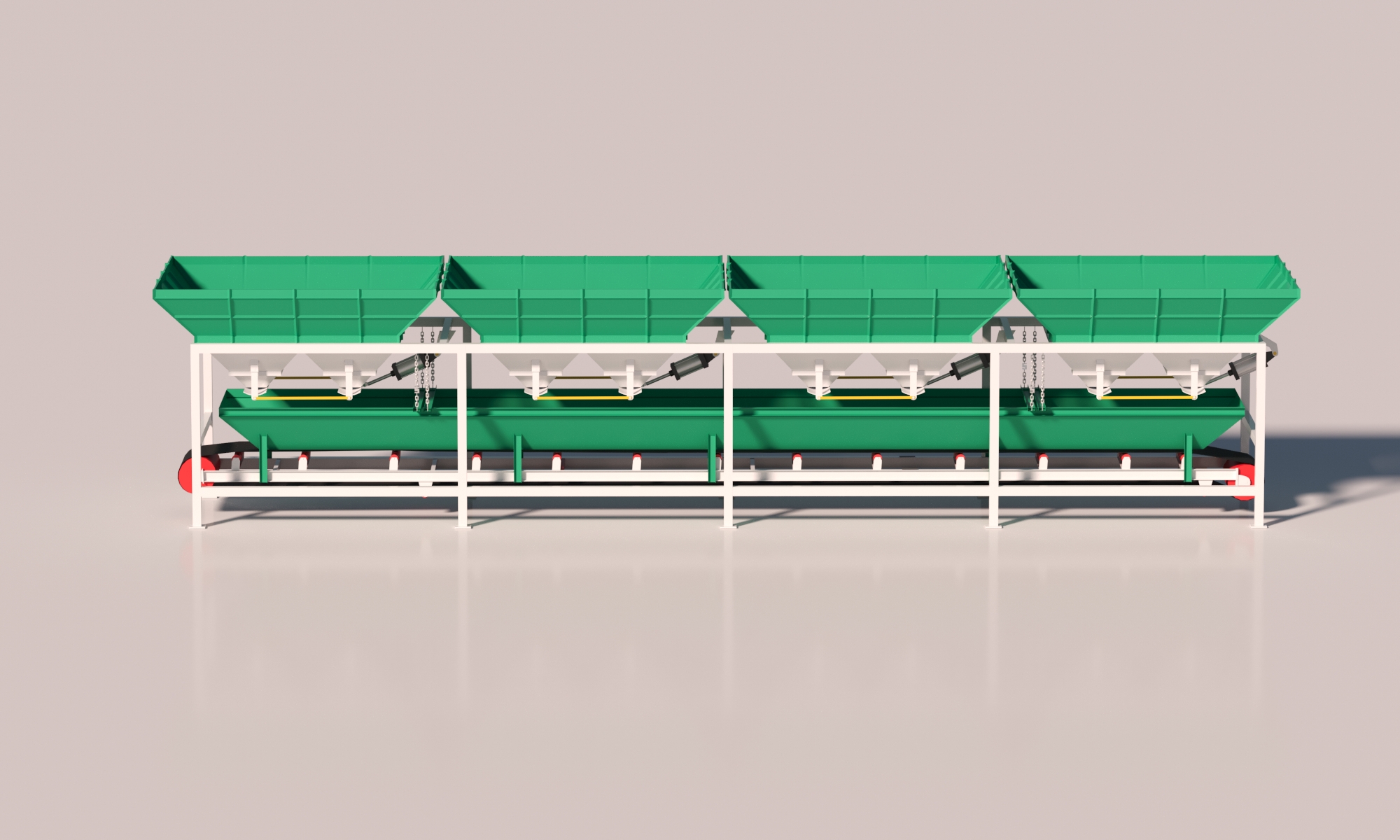

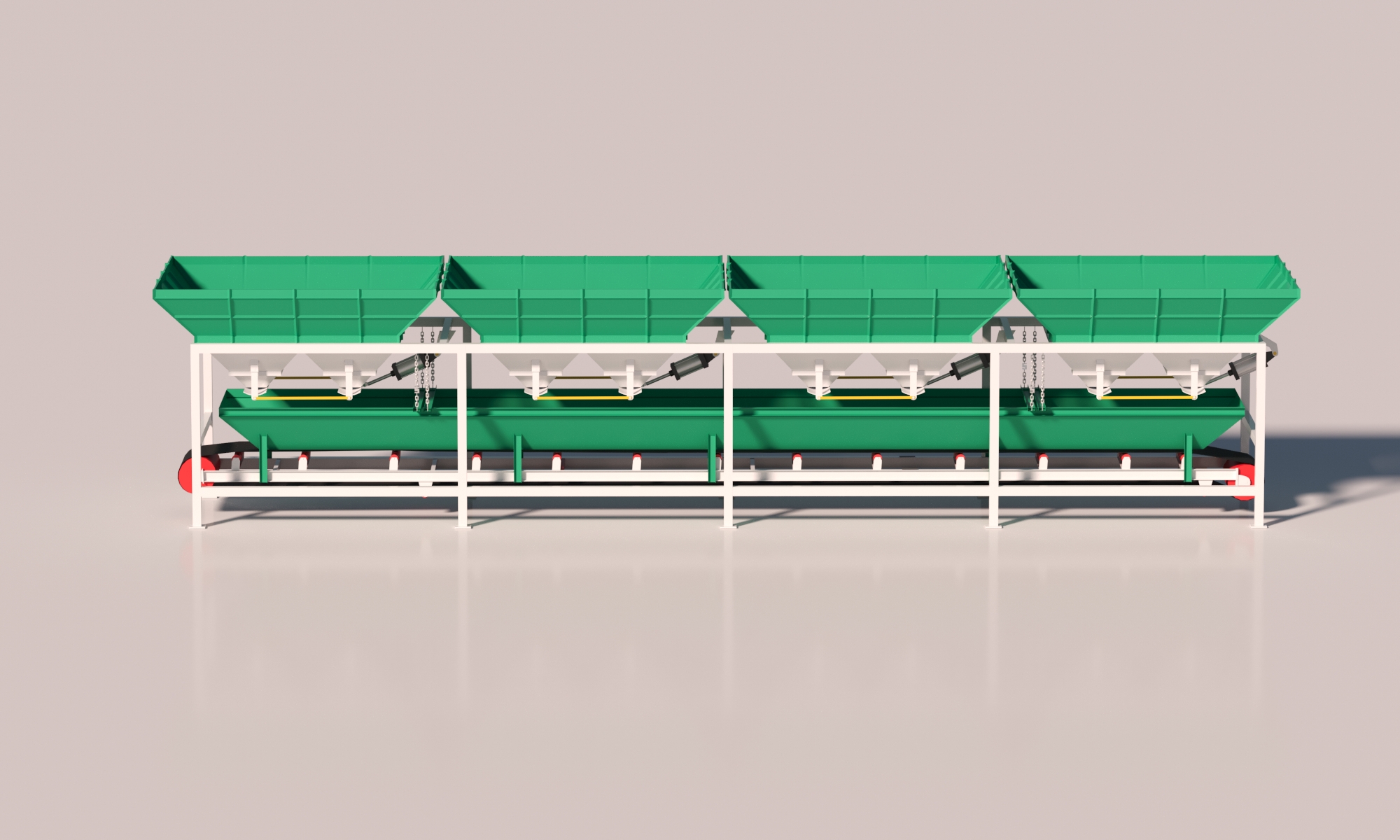

| AG Batcher | 3x3m³ | 3x3m³ | 3x3m³ | 3x3m³ | 3x5m³ | |

| Asphalt storage hopper | 5t | 5t | 5t | 5t | 9t | |

| Product Temp | 120-180℃ adjustable | |||||

| Fuel consumption | 0i:5-8kgt,Coal:13-15kg/t | |||||

Control method | Programmable controller | |||||

| Note: Abowe are stsrdard conlig,ration(lor reference,. We can modily sccording to your requrenents. | ||||||

PRODUCT FEATURES AND DETAILS

*Product Features

SLHB series mobile asphalt mixing plant features:

1、Double drums design,cost-saving for customers.

2、simple structure,easy operation.

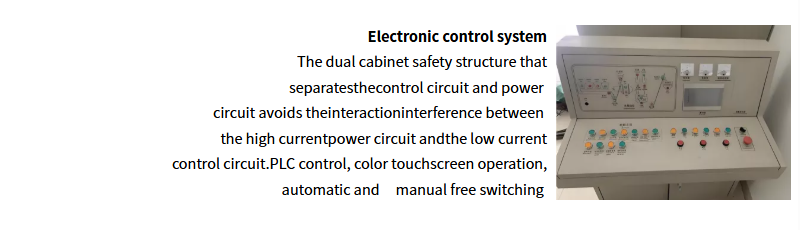

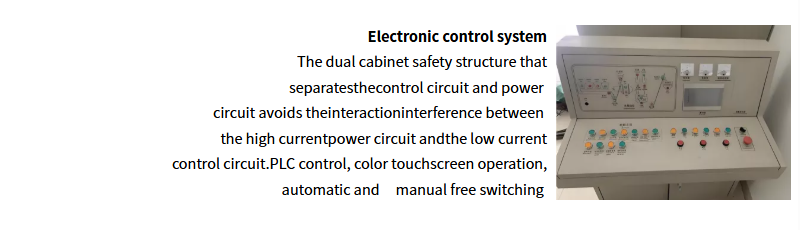

3、PLC control method,easy switch.

4、Chasis structure.good mobility.

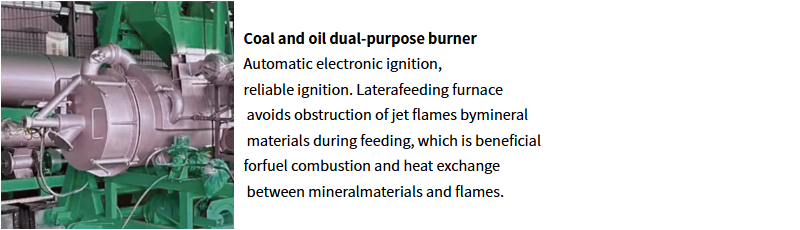

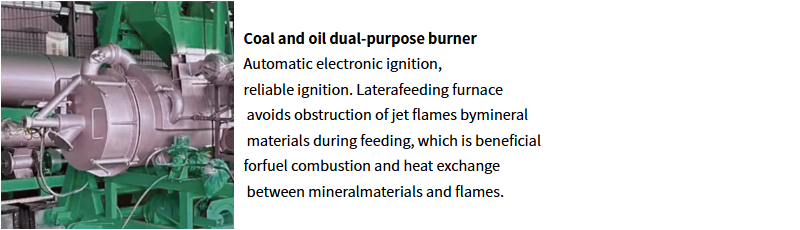

5、Diesel and coal bumer for customer's option.

*Product Features

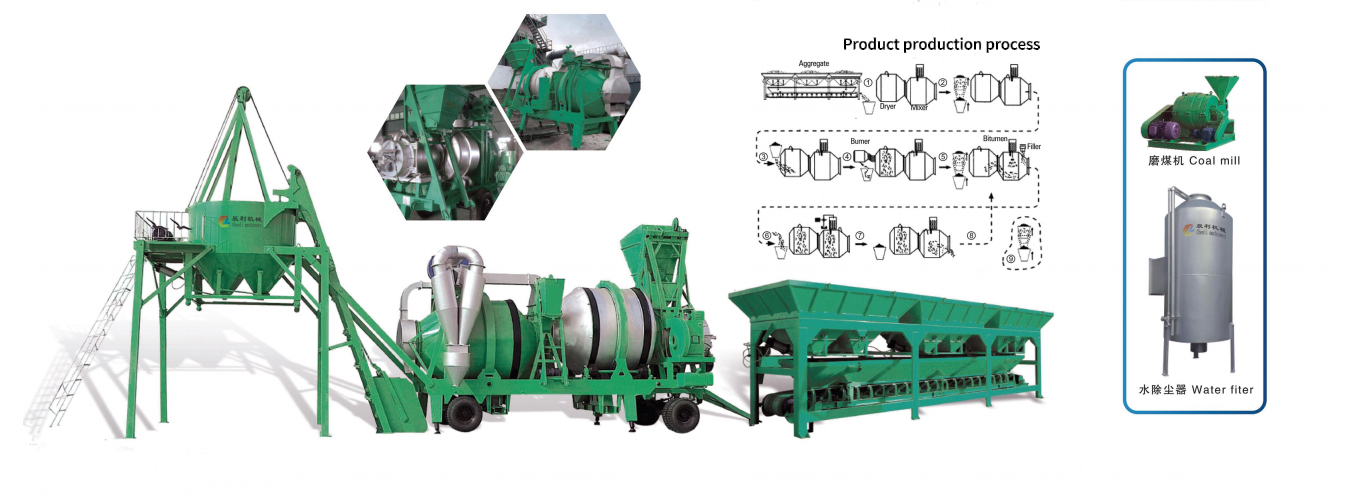

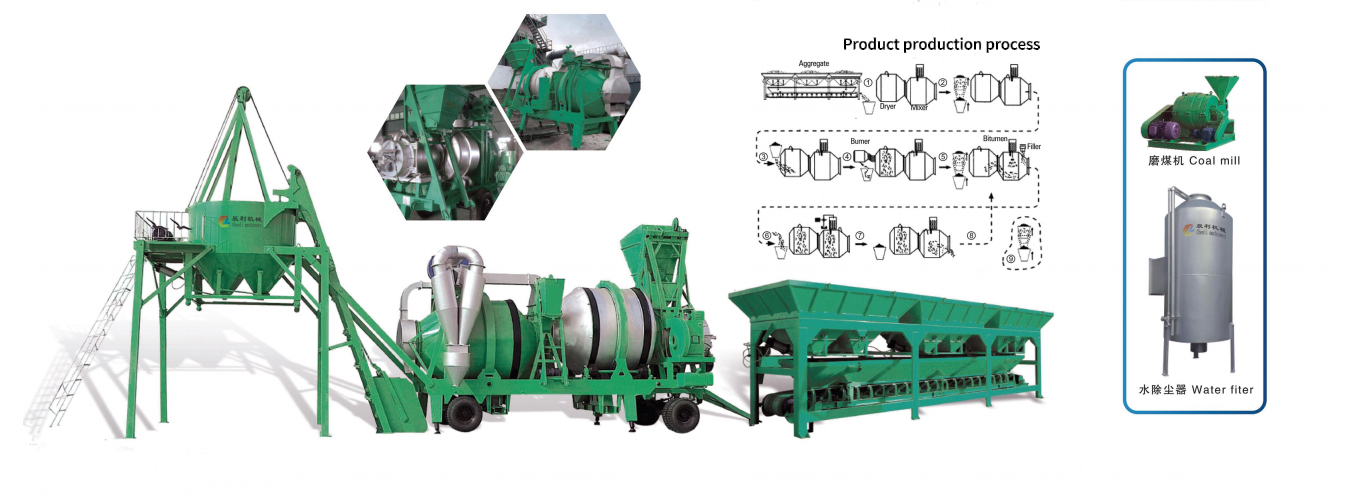

PRODUCT DETAILS PICTURE DISPLAY

PRODUCT SPECIFICATIONS

| Model | SLHB-8 | SLHB-10 | SLH8-15 | SLHB-20 | SLHB-30 | |

| Capacity | 8t/h | 10t/h | 15t/h | 20 t/h | 30 t/h | |

| Total Power | Diesel | 23kw | 27 kw | 32 kw |

45 kw | 63 kw |

| Coal | 39 kw | 43 kw | 51 kw | 70 kw | 84 kw | |

| AG Batcher | 3x3m³ | 3x3m³ | 3x3m³ | 3x3m³ | 3x5m³ | |

| Asphalt storage hopper | 5t | 5t | 5t | 5t | 9t | |

| Product Temp | 120-180℃ adjustable | |||||

| Fuel consumption | 0i:5-8kgt,Coal:13-15kg/t | |||||

Control method | Programmable controller | |||||

| Note: Abowe are stsrdard conlig,ration(lor reference,. We can modily sccording to your requrenents. | ||||||

PRODUCT FEATURES AND DETAILS

*Product Features

SLHB series mobile asphalt mixing plant features:

1、Double drums design,cost-saving for customers.

2、simple structure,easy operation.

3、PLC control method,easy switch.

4、Chasis structure.good mobility.

5、Diesel and coal bumer for customer's option.

*Product Features

PRODUCT DETAILS PICTURE DISPLAY

LBQ SINGLE DRUM MOBILE ASPHALT MIXING PLANT

| Model | LBS-10 | LBS-15 | LBS-20 | LBS-30 | LBS-40 | |

| capacity | 10t/h | 15t/h | 20t/h | 30t/h | 40t/h | |

| Total Power | Diesel | 41.5kw | 54 kw | 63.5 kw | 104.5 kw | 125kw |

| Coal | 57.5 kw | 75 kw | 86.5 kw | 127.5kw | 169kw | |

| AG Batcher | 3m³x3 | 3m³x3 | 3 m³x3 | 5m³x3 | 5m³x3 | |

| Finished prodlct warehouse | 3t | 5t | 5t | 9t | 9t | |

| feed hopper capacity | 500 | 750 | 1000 | 1500 | 1800 | |

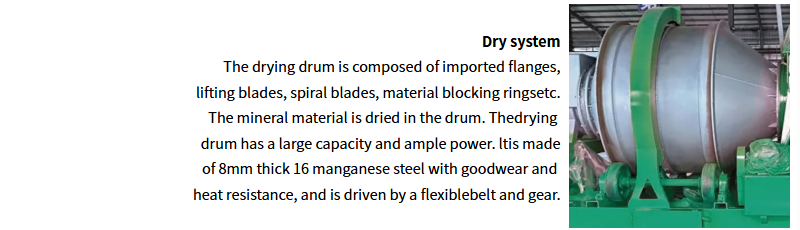

| Drying drumrotation speed (rotation/min) | 18 | 18 | 16 | 16 | 16 | |

| sphere ofapplication | asphalt sand,asphalt gravel, asphalt concrete | |||||

| Finished product temperature | 120-180℃ | |||||

| Fuel consumption | 0i: 5-7.5kg/t,Coal:13-15kg/t | |||||

| Production cycle | 3minutes,i.e.20 batches per hour | |||||

LBQ DOUBLE-DRUM MOBILE ASPHALT MIXING PLANT

| Model | LQY-60 | LQY-80 |

| Total Power | 165 kw | 190 kw |

| Capacity | 60 t/h | 80 t/h |

| Feeding capacity | 1.1m³x2 | 1.2m³x2 |

| Feeding weight | 1.5t each hopper*2 | 1.8t each hopper*2 |

| Product temperature | 120~165°℃adjustable | |

| Material scope | Bitumen sand,Bitumen broken stone,asphlt concete | |

| Fuel consumption | coal:12-15kg/t | |

| Control method | PC+PLCorigrannable electrical control cabinet | |

PRODUCT FEATURES

LQY series forced type mobile asphalt mixing plant features:

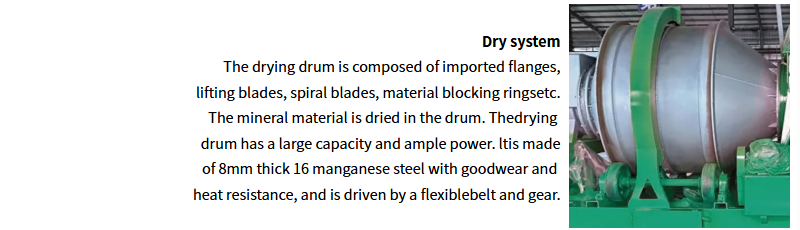

1. The overall design of intemmittent drying drum and twin shaft mixing makes the mixingmore thorough and the finished product better in quality.

2. Forward rotation for drying and reverse rotation for discharging, the overall structure issimple and easy to operate.

3. PLC programmable centralized control, touch screen operation, automatic and manual

modes can be switched freely.

4. The mobile chassis structure makes transportation and installation quick and convenient5. Coal-fired and oil-fired dual-purpose bumers, customers can choose according to theactual requirements.

LQY-60,LOG-80 forced asphalt mixing plant,consists of automatic weighing batcher,double mixers(double hoisting system of mineral aggregates,double burners double dryers, forced mixer, hotasphalt weighing conveyor, filer weighingconveyor,finished-product hopper, cyclonedusr collecting system, double chassis),hydraulic supporter, PLC programmableelectrical room, coal grinding and powderfeeding device etc.

The plant is combined the intermittentdryter and twin-shafts forred mixer as thewhole structure, small area, easy to transferfrom site to site and install, wide scope forfuel application, easy operation, maintainconvenlently, reliable and compactable,good quality of finishedproduct, hightechnology,automatic, high degreeofstandardization, apply to the graded asphaltroad's construction and maintenance.

LBQ SINGLE DRUM MOBILE ASPHALT MIXING PLANT

| Model | LBS-10 | LBS-15 | LBS-20 | LBS-30 | LBS-40 | |

| capacity | 10t/h | 15t/h | 20t/h | 30t/h | 40t/h | |

| Total Power | Diesel | 41.5kw | 54 kw | 63.5 kw | 104.5 kw | 125kw |

| Coal | 57.5 kw | 75 kw | 86.5 kw | 127.5kw | 169kw | |

| AG Batcher | 3m³x3 | 3m³x3 | 3 m³x3 | 5m³x3 | 5m³x3 | |

| Finished prodlct warehouse | 3t | 5t | 5t | 9t | 9t | |

| feed hopper capacity | 500 | 750 | 1000 | 1500 | 1800 | |

| Drying drumrotation speed (rotation/min) | 18 | 18 | 16 | 16 | 16 | |

| sphere ofapplication | asphalt sand,asphalt gravel, asphalt concrete | |||||

| Finished product temperature | 120-180℃ | |||||

| Fuel consumption | 0i: 5-7.5kg/t,Coal:13-15kg/t | |||||

| Production cycle | 3minutes,i.e.20 batches per hour | |||||

LBQ DOUBLE-DRUM MOBILE ASPHALT MIXING PLANT

| Model | LQY-60 | LQY-80 |

| Total Power | 165 kw | 190 kw |

| Capacity | 60 t/h | 80 t/h |

| Feeding capacity | 1.1m³x2 | 1.2m³x2 |

| Feeding weight | 1.5t each hopper*2 | 1.8t each hopper*2 |

| Product temperature | 120~165°℃adjustable | |

| Material scope | Bitumen sand,Bitumen broken stone,asphlt concete | |

| Fuel consumption | coal:12-15kg/t | |

| Control method | PC+PLCorigrannable electrical control cabinet | |

PRODUCT FEATURES

LQY series forced type mobile asphalt mixing plant features:

1. The overall design of intemmittent drying drum and twin shaft mixing makes the mixingmore thorough and the finished product better in quality.

2. Forward rotation for drying and reverse rotation for discharging, the overall structure issimple and easy to operate.

3. PLC programmable centralized control, touch screen operation, automatic and manual

modes can be switched freely.

4. The mobile chassis structure makes transportation and installation quick and convenient5. Coal-fired and oil-fired dual-purpose bumers, customers can choose according to theactual requirements.

LQY-60,LOG-80 forced asphalt mixing plant,consists of automatic weighing batcher,double mixers(double hoisting system of mineral aggregates,double burners double dryers, forced mixer, hotasphalt weighing conveyor, filer weighingconveyor,finished-product hopper, cyclonedusr collecting system, double chassis),hydraulic supporter, PLC programmableelectrical room, coal grinding and powderfeeding device etc.

The plant is combined the intermittentdryter and twin-shafts forred mixer as thewhole structure, small area, easy to transferfrom site to site and install, wide scope forfuel application, easy operation, maintainconvenlently, reliable and compactable,good quality of finishedproduct, hightechnology,automatic, high degreeofstandardization, apply to the graded asphaltroad's construction and maintenance.