English

| Availability: | |

|---|---|

| Quantity: | |

LB1000/LB1250/LB1500/LB2000/2500/LB3000/LB4000/LB5000

chenli

PRODUCT SPECLCATION

PRODUCT REAL SHOT

MAIN COMPONENTS OF THE PRODUCT

The main mixing building usually consists

of a vibratingscreen, a hot material bin,

a weighing hopper, a mixer,an HMA storage

bin, and a loading layer; Each part is

anindependent module, making it

easy to transport andinstall

The power switches of all components can

be controlledthrough the control panel,

making operation and controlsimple,

The control cabinet adopts lP55 safety

protectionlevel and is a containerized

control room with insulationand

sound insulation layers

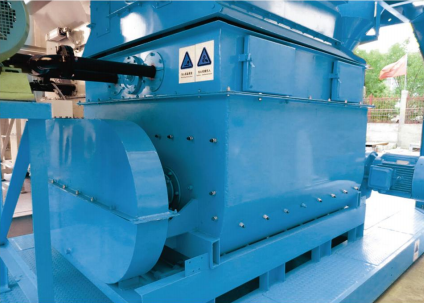

The distance between the blades and the

bottom of themixer reaches the optimal

value. The discharge of themixing tank has been

optimized to shorten the dischargetime.

The large pneumatic door at the bottom of

themixer can quickly release the hot mixture.

Variable frequency control ensures stable feeding

Shortage alarm. Adopting seamless circular belt,

with along service life, the warehouse wall vibrator

avoidsblockage. The hopper is equipped with

an anti largematerial grille with a

mesh size of 100x100 millimeters.

High wear-resistant screen mesh and

high-qualityvibration motor ensure stable operation;

The screenadopts a tensioned installation method,

which is durableand easy to replace.

The internal arrangement of the drum has

beenoptimized to improve the efficiency

of drying andheating. The outside of the

drum is insulated withrock wool and galvanized

iron sheet, which reducesheat loss

and has a beautiful appearance

Bag filter, capable of collecting fine dust;

The dustemitted after dust removal is less

than20mg/Nm3.The high-temperature

resistant filter bagis made of NOMEX material, with a long service lifeand easy replacement.

PRODUCT SPECLCATION

PRODUCT REAL SHOT

MAIN COMPONENTS OF THE PRODUCT

The main mixing building usually consists

of a vibratingscreen, a hot material bin,

a weighing hopper, a mixer,an HMA storage

bin, and a loading layer; Each part is

anindependent module, making it

easy to transport andinstall

The power switches of all components can

be controlledthrough the control panel,

making operation and controlsimple,

The control cabinet adopts lP55 safety

protectionlevel and is a containerized

control room with insulationand

sound insulation layers

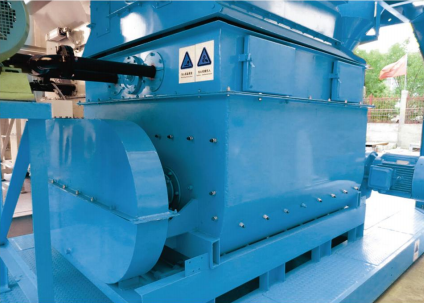

The distance between the blades and the

bottom of themixer reaches the optimal

value. The discharge of themixing tank has been

optimized to shorten the dischargetime.

The large pneumatic door at the bottom of

themixer can quickly release the hot mixture.

Variable frequency control ensures stable feeding

Shortage alarm. Adopting seamless circular belt,

with along service life, the warehouse wall vibrator

avoidsblockage. The hopper is equipped with

an anti largematerial grille with a

mesh size of 100x100 millimeters.

High wear-resistant screen mesh and

high-qualityvibration motor ensure stable operation;

The screenadopts a tensioned installation method,

which is durableand easy to replace.

The internal arrangement of the drum has

beenoptimized to improve the efficiency

of drying andheating. The outside of the

drum is insulated withrock wool and galvanized

iron sheet, which reducesheat loss

and has a beautiful appearance

Bag filter, capable of collecting fine dust;

The dustemitted after dust removal is less

than20mg/Nm3.The high-temperature

resistant filter bagis made of NOMEX material, with a long service lifeand easy replacement.